We have been pretty busy finishing the hydronics, and the duct work. There are a number of threaded fittings in the hydronic system, and some of them have given us an inordinate amount of trouble. But to take things in proper order...

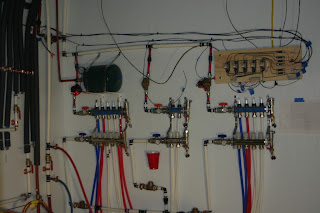

We worked on putting the rest of the pieces together for the hydronics. This gives you an idea of how much plumbing you can stuff on the walls, in the corner of a room. Domestic water supply on the left, and hydronic heating system on the right. I want to put insulation on the PEX in the hydronic system as well, but that may be an item that waits until after I move in.

Since the rough plumbing was signed off on, it was time to close up the

walls in the utility room. We had one more plywood sheet that needed to

go up. We took measurements, and then dad cut some holes in it.

This...

Became this...

There is a little frame that goes in the washing machine box, and that will cover the rough edges of the rectangular hole. The PVC pipe down low, near the gas line, is where the drain and trap will be added on for the washer.

More duct "work" ensued and the place looked like a scene from a sci-fi movie, after they have had an accident on board the ship.

Those two in the foreground, are extending to boxes, and across the floor. At times, we had mom holding them out of our way, just so we could work on the other parts.

Last night we got more of the duct work under control, and cut a couple of them to length, so they were not trailing across the floor anymore.

We got the water coil in its box, mounted on the wall and I put a thermostat inside. The thermostat is wired to one of the pumps in the hydronic system, so if the air coming in is too cold, it will pump warm water over to the coil to warm up the incoming air.

We also added a duct fan on the outlet side to help pull air into the house, and we are going to set it up, so it can also act to recirculate air in the house when I want it to. Hanging on the wall at first, it looked like some sort of jet engine test rig.

Right now with the system turned on, and the fan plugged in, it makes a nice hand warmer, as dad demonstrates here.

Last weekend we called it quits on trying to get the fittings for the hydronic system completely sealed. It is filled with distilled water, so there is very little issue with a bit of leaking. Except for one, the few places it is still leaking, are leaking slowly enough that the floor is drying faster than the water leaks out. So for now, we won't take any more time to pull fittings apart and redo them. We did not have any chewing gum, but bailing wire was used to handle the one leak that is a little faster...a red plastic cup was also employed.

With the control panel wired up, we ran the system. I still need to get some air flushed out of the lines, some wires need to be secured, and a little tweaking to valve settings will be needed for it to work well, but it is basically usable.

This pair of pumps runs whenever the little tank is below its temperature setting, and one of the other pumps is running. These pumps push water through a heat exchanger that I have in a foam box. The heat exchanger and pumps, move heat from the domestic water heater, over to the small water heater tank. The rest of the pumps take the heated water in the small tank, and push it through the water coil, or the tubing embedded in the floor of the house.

We are concentrating on the duct work right now. We are still putting together more plenums to connect the ducts together.

This and some duct fittings that will get put together tomorrow night, will work to route the air returning from the rooms in the house, either to the HRV to have heat removed before being exhausted from the house, or to the supply duct to be delivered back into the house.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment